Frozen Carbonated Beverage (FCB) Dispensers

Frozen carbonated beverages (FCB) offer an exciting way to add maximum profit into your existing beverage program without sacrificing valuable space. Available in 2, 3 and 4-barrel models, Taylor® frozen drink machines are available with a variety of options to send your beverage sales soaring. Similar to slush, FCB is infused with carbonated air to create a fluffy, light frozen drink with a taste that kids of all ages love.Popular in Convenience Stores, Cinemas and Theme Parks, FCB products can generate fun and interest for any foodservice program by mixing multiple flavors, or by creating fun package deals for even more profitable options. With easy-to-use operation, Taylor foodservice equipment delivers consistent quality products draw after draw.

FOUR FLAVOR

Model 349

Freezing Cylinder: Four, 7 quart (6.6 liter)

Dispense a light, fluffy, high overrun slush product in a pressurized system. Optional non-pressurized system produces a wetter, lower overrun slush.

Clear plastic dispensing doors with self closing draw handles are standard. Round dispensing nozzle conveniently fits the hole in domed lids.

Electronic Control

Slushtech™ is standard with our exclusive microprocessor based universal control which regulates refrigeration by measuring product viscosity. Self diagnostic features aid in serviceability.

Syrup

Designed to use FCB syrup in bag-in-box packaging. Optional syrup tank fittings are available for using syrup in tanks.

Carbonation System

Self-contained carbonation system supplies carbonated water at the set pressure. Sure Set Flow Control automatically maintains brix settings by compensating for fluctuations in water, CO2 and syrup pressures. Soda water flow is preset at the factory.

Indicator Lights/Audible Alarm

Lights flash and audible alarm sounds to indicate loss of CO2, water or syrup. If syrup is out on one side, the opposite side will continue to operate. A snooze feature may be activated to silence the alarm for 30 minutes.

Automatic Defrost

Programmable defrost cycles allow the operator to select the time and frequency for defrosting each freezing cylinder independently. The defrost light flashes to warn customers not to draw product from the side that is being defrosted. At the end of the defrost cycle, the freezer automatically returns the product to serving viscosity.

Power Saver

During extended no-use periods, the Power Saver feature may be programmed for either Standby or Rest Mode. Standby Mode maintains product in freezing cylinder between 35 & 40° F (1.6 & 4.4° C) for quickest return to serving product. Rest Mode shuts down the refrigeration system for the most energy savings. Start and end times may be programmed independently for seven cycles.

Air Filter

Removable, cleanable air filters help keep condensers clean for optimal refrigeration system performance.

Installation: Floor

Number of Flavors: 4

Freezing Cylinder QTY: 4

Freezing Cylinder Size (qt/l): 7/6.6

Mix Delivery System: Gravity

Refrigeration Control: Viscosity

Dimensions w/d/h (in/mm)

31-3/8″ (w)

797mm (w)

40-3/8″ (d)

1026mm (d)

56-13/16″ (h)

1443mm (h)

Net Weight (Lbs/Kg)

896.0 lbs

405.9 kg

FOUR FLAVOR

Model C302

Freezing Cylinder: Four, 7 quart (6.6 liter)

Air is discharged out the top of the unit to accommodate tight counter space. Optional cart converts the unit to a self-contained floor model, and provides storage for the syrup.

Clear plastic dispensing doors allow customers to see slush being made. Self closing draw handles are standard. Round dispensing nozzle conveniently fits the hole in domed lids. Push style dispensing handle provides for 2010 Americans with Disabilities Act (ADA) compliant dispensing height.

Indicator Lights/Audible Alarm

Lights illuminate and audible alarm sounds to indicate loss of CO2, water or syrup on the affected freezing cylinder. The other flavors will continue to operate when one loses syrup. A snooze feature may be activated to silence the alarm for 30 minutes.

Automatic Defrost

Programmable defrost cycles allow the operator to select the time and frequency for defrosting each freezing cylinder independently. The defrost light flashes to warn customers not to draw product from the side that is being defrosted. At the end of the defrost cycle, the freezing cylinder automatically returns to the freeze-down mode.

Power Saver

During extended no-use periods, the Power Saver feature may be programmed for either Standby or Rest Mode. Standby Mode maintains product in freezing cylinder between 35 & 40°F (1.6 & 4.4°C) for quickest return to serving product. Rest Mode shuts down the refrigeration system for the most energy savings. Start and end times may be programmed independently for seven cycles.

Sure Set™ Flow Control

Automatically maintains brix settings by compensating for fluctuations in water, CO2 and syrup pressures. Water flow is preset at the factory.

Electronic Viscosity Control

Slushtech™ is standard with our exclusive microprocessor based universal control which regulates refrigeration by measuring product viscosity.

Air Filter

Removable, cleanable air filter helps keep condenser clean for optimal refrigeration system performance.

Merchandisingr

LED display backlights translight and illuminates clear dispensing doors to draw customer attention. This display provides energy efficient, even, consistent lighting.

Installation: Countertop (Floor – with optional cart)

Number of Flavors: 4

Freezing Cylinder QTY: 4

Freezing Cylinder Size (qt/l): 7/6.6

Mix Delivery System: Pump

Refrigeration Control: Viscosity

Dimensions w/d/h (in/mm)

30-3/8″ (w)

771mm (w)

35″ (d)

889mm (d)

40-5/8″ (h)

1032mm (h)

Net Weight (Lbs/Kg)

675.0 lbs

306.2 kg

FOUR FLAVOR

Model C314

Freezing Cylinder: Four, 7 quart (6.6 liter)

Optional cart converts the unit to a self-contained floor model, and provides storage for the syrup.

Clear plastic dispensing doors allow customers to see slush being made. Self closing draw handles are standard. Round dispensing nozzle conveniently fits the hole in domed lids. Push style dispensing handle provides for 2010 Americans with Disabilities Act (ADA) compliant dispensing height.

Indicator Lights/Audible Alarm

Lights illuminate and audible alarm sounds to indicate loss of CO2, water or syrup on the affected freezing cylinder. The other flavors will continue to operate when one loses syrup. A snooze feature may be activated to silence the alarm for 30 minutes.

Automatic Defrost

Programmable defrost cycles allow the operator to select the time and frequency for defrosting each freezing cylinder independently. The defrost light flashes to warn customers not to draw product from the side that is being defrosted. At the end of the defrost cycle, the freezing cylinder automatically returns to the freeze-down mode.

Power Saver

During extended no-use periods, the Power Saver feature may be programmed for either Standby or Rest Mode. Standby Mode maintains product in freezing cylinder between 35 & 40°F (1.6 & 4.4°C) for quickest return to serving product. Rest Mode shuts down the refrigeration system for the most energy savings. Start and end times may be programmed independently for seven cycles.

Sure Set™ Flow Control

Automatically maintains brix settings by compensating for fluctuations in water, CO2 and syrup pressures. Water flow is preset at the factory.

Electronic Viscosity Control

Slushtech™ is standard with our exclusive microprocessor based universal control which regulates refrigeration by measuring product viscosity.

Air Filter

Removable, cleanable air filter helps keep condenser clean for optimal refrigeration system performance.

Merchandisingr

LED display backlights translight and illuminates clear dispensing doors to draw customer attention. This display provides energy efficient, even, consistent lighting.

Installation: Countertop (Floor – with optional cart)

Number of Flavors: 4

Freezing Cylinder QTY: 4

Freezing Cylinder Size (qt/l): 7/6.6

Mix Delivery System: Pump

Refrigeration Control: Viscosity

Dimensions w/d/h (in/mm)

30″ (w)

762mm (w)

35-7/8″ (d)

911mm (d)

40-1/2″ (h)

1029mm (h)

Net Weight (Lbs/Kg)

632.0 lbs

287.0 kg

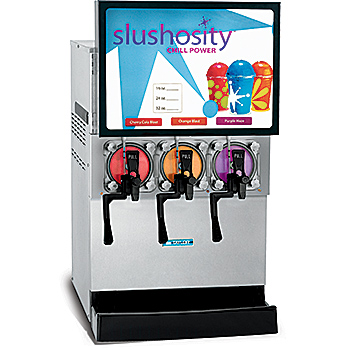

THREE FLAVOR

Model C303

Freezing Cylinder: Three, 7 quart (6.6 liter)

Optional nonpressurized system produces a wetter, lower overrun slush. Air is discharged out the top of the unit to accommodate tight counter space. Optional cart converts the unit to a self-contained floor model, and provides storage for the syrup.

Clear plastic dispensing doors allow customers to see slush being made. Self closing draw handles are standard. Round dispensing nozzle conveniently fits the hole in domed lids.

Indicator Lights/Audible Alarm

Lights illuminate and audible alarm sounds to indicate loss of CO2, water or syrup on the affected freezing cylinder. The other flavors will continue to operate when one loses syrup. A snooze feature may be activated to silence the alarm for 30 minutes.

Automatic Defrost

Programmable defrost cycles allow the operator to select the time and frequency for defrosting each freezing cylinder independently. The defrost light flashes to warn customers not to draw product from the side that is being defrosted. At the end of the defrost cycle, the freezing cylinder automatically returns to the freeze-down mode.

Power Saver

During extended no-use periods, the Power Saver feature may be programmed for either Standby or Rest Mode. Standby Mode maintains product in freezing cylinder between 35 & 40°F (1.6 & 4.4°C) for quickest return to serving product. Rest Mode shuts down the refrigeration system for the most energy savings. Start and end times may be programmed independently for seven cycles.

Sure Set™ Flow Control

Automatically maintains brix settings by compensating for fluctuations in water, CO2 and syrup pressures. Water flow is preset at the factory.

Electronic Viscosity Control

Slushtech™ is standard with our exclusive microprocessor based universal control which regulates refrigeration by measuring product viscosity.

Air Filter

Removable, cleanable air filter helps keep condenser clean for optimal refrigeration system performance.

Merchandisingr

LED display backlights translight and illuminates clear dispensing doors to draw customer attention. This display provides energy efficient, even, consistent lighting.

Installation: Countertop (Floor – with optional cart)

Number of Flavors: 3

Freezing Cylinder QTY: 3

Freezing Cylinder Size (qt/l): 7/6.6

Mix Delivery System: Pump

Refrigeration Control: Viscosity

Dimensions w/d/h (in/mm)

24-3/8″ (w)

619mm (w)

35-7/8″ (d)

911mm (d)

41-5/8″ (h)

1057mm (h)

Net Weight (Lbs/Kg)

441.0 lbs

200.3 kg

TWO FLAVOR

Model C300

Freezing Cylinder: Two, 7 quart (6.6 liter)

Dispense a light, fluffy, high overrun slush product in a pressurized system from this modular, counter-top freezer. Optional nonpressurized system produces a wetter, lower overrun slush.

Clear plastic dispensing doors allow customers to see slush being made. Self closing draw handles are standard. Round dispensing nozzle conveniently fits the hole in domed lids.

Indicator Lights/Audible Alarm

Lights illuminate and audible alarm sounds to indicate loss of CO2, water or syrup on the affected freezing cylinder. The other flavors will continue to operate when one loses syrup. A snooze feature may be activated to silence the alarm for 30 minutes.

Automatic Defrost

Programmable defrost cycles allow the operator to select the time and frequency for defrosting each freezing cylinder independently. The defrost light flashes to warn customers not to draw product from the side that is being defrosted. At the end of the defrost cycle, the freezing cylinder automatically returns to the freeze-down mode.

Power Saver

During extended no-use periods, the Power Saver feature may be programmed for either Standby or Rest Mode. Standby Mode maintains product in freezing cylinder between 35 & 40°F (1.6 & 4.4°C) for quickest return to serving product. Rest Mode shuts down the refrigeration system for the most energy savings. Start and end times may be programmed independently for seven cycles.

Sure Set™ Flow Control

Automatically maintains brix settings by compensating for fluctuations in water, CO2 and syrup pressures. Water flow is preset at the factory.

Electronic Viscosity Control

Slushtech™ is standard with our exclusive microprocessor based universal control which regulates refrigeration by measuring product viscosity.

Air Filter

Removable, cleanable air filter helps keep condenser clean for optimal refrigeration system performance.

Merchandisingr

LED display backlights translight and illuminates clear dispensing doors to draw customer attention. This display provides energy efficient, even, consistent lighting.

Installation: Countertop (Floor – with optional cart)

Number of Flavors: 2

Freezing Cylinder QTY: 2

Freezing Cylinder Size (qt/l): 7/6.6

Mix Delivery System: Pump

Refrigeration Control: Viscosity

Dimensions w/d/h (in/mm)

17-5/16″ (w)

440mm (w)

34-3/16″ (d)

858mm (d)

35-5/8″ (h)

905mm (h)

Net Weight (Lbs/Kg)

335.0 lbs

152.0 kg